Variable Speed Drives are used to regulate the speed and torque of electric motors by controlling the frequency and voltage of the power supplied. Instead of running equipment at a constant, full-speed rate, regardless of actual demand, a VSD adjusts motor output in real time, improving energy efficiency, reducing mechanical wear, and allowing for smoother, more responsive operation.

These devices are also referred to as Variable Frequency Drives (VFDs) or Adjustable Speed Drives (ASDs), depending on the application and region. These days, some equipment is supplied with a built-in VSD, but older equipment may lack this feature. Retrofitting a VSD provides an efficient way to enhance control and reduce energy use without full-scale equipment replacement. To make the most of this upgrade, it’s smart to work with an experienced electrical services provider who can ensure the installation is safe, efficient and fits smoothly into your operations.

The following section explains how VSDs work, the key components involved, and how they interact to deliver smarter, more efficient motor control.

What does a VSD do?

Most motors run on fixed-frequency AC power (typically 50 Hz in Australia), which means they operate at a constant speed. A VSD interrupts this default setting, allowing the motor to operate at the speed required for the task, whether that is slower during low demand or faster when needed.

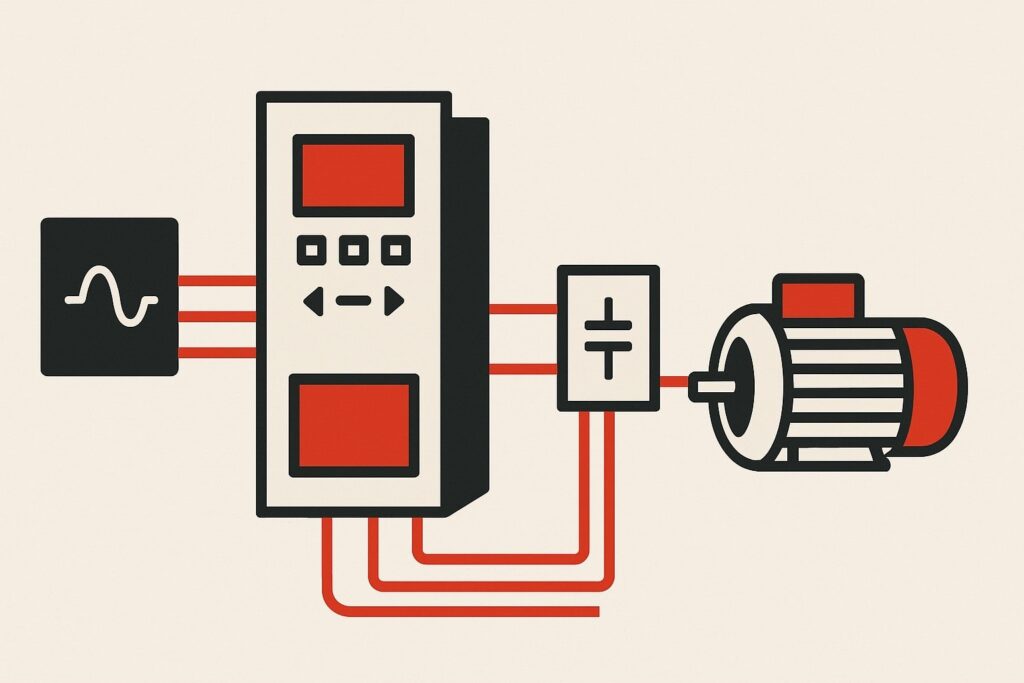

The VSD works by converting incoming AC (alternating current) power into DC (direct current) using a rectifier. This DC power is then stabilised by a component known as the DC bus. Finally, an inverter within the drive converts the DC power back into AC, but this time, at a variable frequency and voltage, allowing precise control over motor speed and torque.

This ability to modulate power in real time means that motors no longer have to operate at full speed continuously. Instead, they can ramp up slowly, maintain an optimal speed based on system load, and reduce output when demand drops, all without stopping the motor entirely.

For businesses, the ability to adjust motor speed in real time translates to operational advantages. One of the most notable benefits is improved energy efficiency. Unlike fixed-speed motors, which operate at full capacity regardless of demand, VSDs enable motors to scale their output based on actual requirements. This means systems such as pumps and fans can run at lower speeds during off-peak periods, dramatically reducing power consumption and lowering energy bills.

In addition to energy savings, VSDs help extend the life of equipment. By enabling smooth acceleration and deceleration, they reduce mechanical stress on components such as belts, bearings, and shafts. This minimises wear and tear, lowers the risk of breakdowns, and reduces the frequency and cost of maintenance.

VSDs also offer greater control over processes in industries where precision matters, such as manufacturing, water treatment, or heating, ventilation, and air conditioning (HVAC). Being able to fine-tune speed and torque allows for more stable performance and consistent output. This enhanced control not only improves product quality and system reliability but also supports automation and integration with building management or control systems.

The improved efficiency and lower emissions associated with VSDs contribute to environmental compliance. Businesses aiming to meet sustainability targets or reduce their carbon footprint can benefit from the measurable reductions in energy use that VSDs deliver.

Components and operation of a VSD system

The components of a Variable Speed Drive (VSD) system work in sequence to convert a fixed-frequency electrical input into a variable-frequency output, providing precise control over motor speed and torque. This process enables electric motors to operate more efficiently by adjusting their performance in real-time to suit changing system demands.

Converting AC to DC

The operation begins when the VSD receives standard AC (alternating current) power from the electrical supply. The first internal component, known as the rectifier, converts this AC into DC (direct current), a format that can be more easily manipulated for speed control.

Regulating and reversing power flow

Next, the power flows through the DC bus, or intermediate circuit, which smooths out voltage fluctuations and temporarily stores energy. This stabilised power ensures consistent performance in the next stage. The inverter then takes over, transforming the DC back into AC, but this time at a variable frequency and voltage. By using high-speed switching, the inverter generates a waveform that controls the speed and torque of the motor. This is what enables the VSD to deliver highly responsive, real-time adjustments to motor performance.

Responding to system demands

Overseeing the entire process is the control interface, which can be either a manual input or an integrated system, such as a Building Management System (BMS) or Programmable Logic Controller (PLC). This interface instructs the drive on how to respond to load changes or operational conditions, automatically adjusting the motor output based on demand.

Coordinated control for greater efficiency

By coordinating these components and processes, a VSD system replaces the traditional fixed-speed approach with a more dynamic, efficient, and intelligent solution. Rather than running motors at full speed continuously, VSDs allow for a tailored response to varying loads, helping to reduce energy waste, minimise wear on mechanical parts, and extend equipment life.

Controlling Motor Speed and Torque

One of the core functions of a variable speed drive is its ability to precisely control both the speed and torque of an electric motor. This level of control is crucial in systems where load conditions fluctuate or where stable performance is imperative.

In AC motors, speed is directly tied to the frequency of the electrical power supplied. As the frequency increases, the motor runs faster; conversely, as the frequency decreases, the motor slows down. For instance, a standard AC motor running at 50 Hz could operate at around 1,500 RPM. Reducing the frequency to 25 Hz through the VSD slows the motor to approximately half that speed. This dynamic frequency control allows motors to adjust speed smoothly without relying on mechanical throttling or control valves.

However, changing motor speed alone isn’t enough. Many systems require stable torque to perform reliably, especially at lower speeds. Torque, the force that enables the motor to turn, naturally drops as speed decreases unless voltage is also adjusted. To address this, VSDs apply intelligent voltage-to-frequency ratios, maintaining adequate torque where it is needed. This is especially useful in constant-torque applications, such as conveyors or positive-displacement pumps, where load demands remain high even at low speeds.

Take, for example, a water pump in a building’s HVAC system. Under lower cooling demand, the system doesn’t need full flow. A VSD can reduce the motor speed to slow the pump, thereby reducing energy consumption. With the real-time adjustments in voltage and frequency, the VSD ensures the pump continues to deliver a consistent and stable flow, without the pressure spikes, mechanical strain, or inefficiencies that often result from using traditional control valves or bypass systems.

By managing both speed and torque in response to real-time operating conditions, VSDs improve process stability, enhance equipment longevity, and deliver meaningful energy savings. This level of control is what makes VSDs so valuable across a wide range of commercial, industrial, and infrastructure applications.

Where VSDs are used

VSDs are used in a wide range of industries and facilities where motor speed needs to be adjusted in response to demand, including:

- Conveyors – adjust speed to match production flow and energy use.

- Mixers – control mixing intensity for different materials and batch requirements.

- Grinders – optimise motor speed to reduce wear and improve efficiency.

- Irrigation pumps – deliver water based on crop needs and environmental conditions.

- Processing equipment – match speed to processing stage for better control.

- Pumps (water/wastewater) – adjust flow based on real-time system demand and load.

- Aerators – manage airflow efficiently to maintain treatment process stability.

- HVAC Systems – vary fan or pump speed for temperature and pressure control.

- Chillers – match cooling output to building load and operating conditions.

- Lifts and Elevators – smooth acceleration and deceleration for comfort and motor protection.

- Variable flow heating and cooling – adjust delivery based on occupancy or system load changes.

Compatibility with different machines and equipment

Not all motors and machines are equally suited to adding a VSD. While some equipment is designed with VSD compatibility in mind, others may require modification, and a portion of legacy or specialised machinery may be incompatible altogether.

Many newer pieces of equipment, particularly those where variable speed is integral to performance, are supplied with built-in VSDs. This includes advanced HVAC systems, packaged pump sets, and certain types of industrial electrical machinery where manufacturers prioritise energy efficiency or process control from the outset.

In other situations, fixed-speed equipment can be successfully retrofitted with a VSD. This is a common and cost-effective approach when businesses want to improve energy efficiency or enhance control without replacing the entire system. Retrofitting is often straightforward when dealing with standard three-phase induction motors, particularly if the motor is already rated for inverter use. In these cases, a VSD can be added to control speed, reduce start-up stress, and align motor performance with real-time demand.

However, some machines and motors are not suitable for VSD integration. Small single-phase motors, commonly found in domestic or portable equipment, are generally incompatible due to their internal design and inability to respond reliably to changes in frequency. Older three-phase motors or lower-quality units may lack the insulation and thermal capacity needed to withstand the operating conditions introduced by a VSD. In such cases, attempting to retrofit a VSD can lead to overheating, premature failure, or erratic performance.

Practical limitations can also affect compatibility. Space constraints, lack of ventilation, or insufficient integration with control systems such as PLCs or BMS platforms may make a retrofit unfeasible without additional upgrades. Before fitting a VSD, it is essential to assess the existing motor, evaluate load characteristics, and ensure the system can accommodate the electrical and environmental demands of a drive.

Most modern VSDs can be integrated with existing PLCs, SCADA systems, and Building Management Systems. This allows operators to monitor motor status, adjust settings remotely, and log performance data for analysis, supporting both operational efficiency and preventive maintenance strategies.

Ultimately, while many machines can benefit from VSD technology, compatibility depends on both the motor’s technical specifications and the practical requirements of the application. A professional assessment will help determine whether integration is straightforward, requires minor modification, or is not advisable for the existing setup.

Benefits of VSDs

One of the most immediate benefits of VSDs is improved energy efficiency. The ability to match motor speed to actual demand significantly reduces energy consumption, particularly in partial-load conditions where fixed-speed motors would otherwise waste power. When motors run for extended periods or operate under varying loads, the energy savings from a VSD can result in a payback period of 6 to 24 months. This depends on motor size, duty cycle, and electricity rates.

Another key benefit is the soft-start and soft-stop functionality. Unlike traditional motors that start abruptly at full speed, a VSD gradually ramps up the motor. This controlled acceleration minimises mechanical shock to belts, couplings, and gearboxes, helping to reduce wear and extend the lifespan of critical components. Similarly, slowing the motor down gently during shutdown prevents sudden stops that can strain the system.

VSDs also enhance compatibility with automation and process control systems. They can be easily integrated with PLCs, BMS, and other control platforms to respond dynamically to changing operating conditions. This level of responsiveness enables more precise regulation of speed, pressure, or flow, which is valuable in manufacturing, water treatment, and HVAC applications where stability and efficiency are closely linked.

Over time, the use of VSDs contributes to lower maintenance costs. By reducing mechanical stress and avoiding unnecessary runtime at full speed, the overall wear on motors and connected equipment is reduced. This not only helps prevent breakdowns but also extends service intervals, reduces downtime, and enables more predictable and planned maintenance.

What to Consider Before Installing a VSD

While Variable Speed Drives offer clear benefits, successful installation and long-term performance rely on selecting the right equipment, planning the setup properly, and ensuring the system is maintained. As stated previously, not all motors are suitable for VSD use, older or lower-grade motors may not tolerate variable voltage and frequency conditions. If the motor is not inverter-rated, problems such as overheating or insulation failure can occur, leading to breakdowns.

Electrical interference is another important consideration. VSDs operate using high-speed switching, which can introduce harmonics into the system. If unmanaged, this electrical noise may affect nearby equipment or reduce overall power quality. In sensitive environments, filters or mitigation devices may be needed to ensure stability.

Heat management is also critical. VSDs generate heat during normal operation and need adequate ventilation to avoid performance issues. Installing a drive in a poorly ventilated or confined space can shorten its service life or cause it to shut down unexpectedly.

Upfront costs and setup time should also be taken into account. While the energy savings often offset the investment over time, VSDs can cost more to install than fixed-speed alternatives. In more complex systems, configuring the drive to match operational needs may require engineering input.

Common faults, such as system tripping, motor instability, or poor performance, typically indicate installation or setup issues rather than faults in the VSD itself. Most problems arise from improper motor matching, poor ventilation, incorrect programming, or a lack of integration with the broader system.

Sydney Engineering provides comprehensive VSD support and mechanical engineering services, from selecting the right drive and ensuring proper installation to troubleshooting, repairs, and ongoing preventative maintenance. Sydney Engineering can also assist with system design and upgrades, helping businesses extend the life of their equipment, improve performance, and meet energy efficiency targets.

Issues that can occur with variable speed drives

Although Variable Speed Drives are highly effective when properly selected and installed, issues can still arise over time, especially in industrial environments where equipment is exposed to fluctuating loads, environmental stress, and operational misuse.

Environmental conditions

Dust, moisture, and high ambient temperatures can impact the performance of a VSD. Enclosures, filters, and heat management should be part of the installation plan in such environments.

Power supply fluctuations

Inconsistent power supply, such as voltage dips, surges, or phase imbalance, can cause a VSD to trip or shut down unexpectedly. While many drives include protective features, repeated interruptions can reduce service life or lead to faults in connected equipment. In high-risk areas, voltage conditioning or surge protection may be necessary.

Cable interference and shielding

VSDs can introduce electrical noise (EMI) into nearby control or communication cables. Without proper cable shielding or grounding, this interference can affect sensors, PLCs, or other nearby electronics. Poor cable layout is a common cause of performance problems in automated environments.

Configuration and tuning errors

Many VSDs offer advanced control features; however, incorrect parameter settings can lead to poor performance or system instability. Examples include oversensitive fault detection, unstable motor start-up behaviour, or inconsistent torque delivery. Proper commissioning and tuning are essential, especially in complex or multi-motor systems.

Operation Misuse or bypass

In some cases, operators may override drive functions, either manually forcing motors to run at full speed or disabling fault alarms. While this may seem like a temporary fix, it can lead to long-term damage or mask underlying issues.

Signs your equipment could benefit from a VSD

Identifying whether your equipment would perform better with a VSD often comes down to recognising patterns of inefficiency, stress, or recurring faults in your current system. One of the most noticeable indicators is a loud or jarring startup. When motors engage abruptly and at full speed, it can create a sudden surge of mechanical and electrical strain.

Overheating is another red flag. If motors regularly run hot or require additional cooling to maintain safe operation, it may be due to the constant, full-speed performance that a fixed system imposes. Unexpected shutdowns or system tripping can also indicate problems that a VSD could help resolve. When motors are forced to operate outside their ideal conditions, protective systems are more likely to activate, interrupting workflows and increasing downtime.

Frequent motor replacements or recurring failures are clear signs that something is putting undue stress on the system. In many cases, this is a result of motors running harder than necessary, with no means of adjusting to fluctuations in demand. Over time, this accelerates wear and leads to premature failure.

When these signs are present, it is worth evaluating whether a VSD could improve performance, reduce stress on equipment, and create a more responsive and efficient system overall.

Sydney Engineering’s VSD Services

Whether you are upgrading an existing system or planning a new installation, Sydney Engineering delivers a full range of Variable Speed Drives and reliable engineering solutions for your next project. Our team understands that each site operates differently, and we offer practical guidance from early planning through to ongoing system optimisation.

Sydney Engineering handles complete VSD installation and commissioning, ensuring the drive is correctly matched to the motor, load, and control systems. Our commissioning process is thorough, with fine-tuning to ensure smooth operation, optimal energy efficiency, and integration with building management systems or automated controls as needed.

With a strong focus on safety, reliability, and performance, Sydney Engineering delivers VSD solutions backed by years of hands-on experience in motor control systems. Whether it is a new installation or a system upgrade, we help ensure your equipment operates efficiently and meets the demands of your site.